PSD Three-Phase Pad-Mounted Transformers Help

Effective Date: July 2024

Links inside This Document

FM (Factory Mutual) and UL (Underwriters Laboratories)

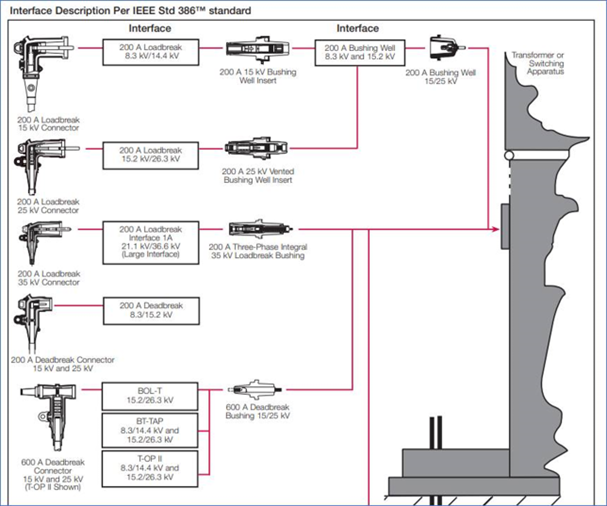

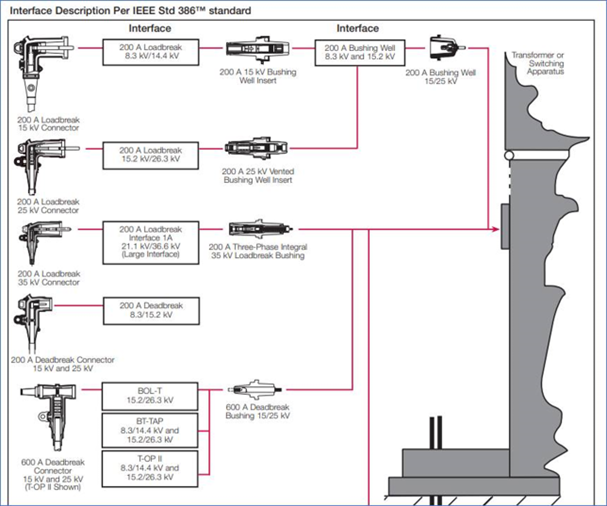

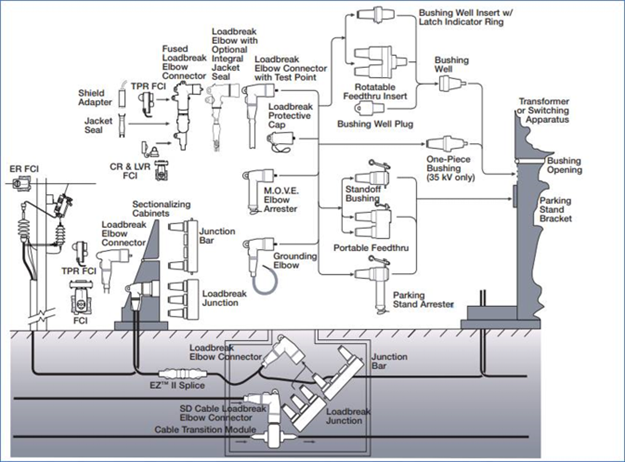

Bushing Inserts elbow arrestor interfaces

Mechanical Requirements / Limits

VFI (Vacuum Fault Interrupter)

|

DOMESTIC PREFERENCE STATUTES |

Regulation Citation |

Regulation Citation |

|

Buy America Act |

Build America / Buy America (BABA) Infrastructure Investment & Jobs Act 41 USC 8301 Sec. 709001 |

Product must be manufactured in the US and cost of US components must be greater than 55% of the total cost of all components. |

|

Buy America Act |

Federal Highway Administration (FHWA) 23 CFR-635.410 & 23 USC-313 |

1. Must be manufactured in the United States, 2. Must be Build America, Buy America compliant (55% domestic content), 3. If the cost of the iron/steel in the transformer is the majority (51% or more) of the cost of components, then it is considered an Iron & Steel product and must have a domestic iron & steel certification. |

|

Buy America Act |

Federal Railroad Administration (FRA) 49 USC - 22905 |

If product is an integral part of an electrical distribution SYSTEM and is manufactured in the United States. |

|

Buy America Act |

Federal Transit Administration (FTA) 49 CFR - 661 |

If product is an integral part of an electrical distribution SYSTEM and is manufactured in the United States. |

|

Buy American (FAA) |

Federal Aviation Administration (FAA) 49 USC - 50101 |

Products are manufactured in the US and all the materials are of US Origin. Waiver allowed if materials exceed 60% of US content. |

|

Buy American Act |

48 CFR - 25.1 (Supplies) 41 USC-8301 |

End product is manufactured in the US and is of the same general offering supplied to both the govt and the commercial markets. |

|

Buy American Act |

48 CFR - 25.2 (Construction) 41 USC-8301 |

End product is manufactured in the US and is of the same general offering supplied to both the govt and the commercial markets. |

|

Buy American Act |

American Reinvestment & Recovery Act (ARRA) 48 CFR - 25.6 |

End product is manufactured in the US and is of the same general offering supplied to both the govt and the commercial markets. |

|

Buy American Act |

Balance of Payments Program 48 CFR - 252.225-7000 and 7001 |

End product is manufactured in the US and is of the same general offering supplied to both the govt and the commercial markets. |

|

Buy American Act |

Free Trade Agreement 48 CFR - 252.225-7036. Also FAR 52.225-11 & 52.225-12 |

End product is manufactured in the US and is of the same general offering supplied to both the govt and the commercial markets. |

|

Buy American Act |

Trade Agreements Act (TAA) 48 CFR-25.4 & 225.4 and 19 USC & 2501-2581 |

End product must be mfg in the US or country having a FTA with the US (i.e., MX, CA). |

|

Inflation Reduction Act |

Inflation Reduction Act (IRA) |

Made in US and manufactured product. Direct components (raw material origin does not matter) in unit is counted toward % of total value of unit. |

FM (Factory Mutual) and UL (Underwriters Laboratories):

The following provides information with regards to Eaton’s offerings and limitations with regards to FM approval, UL listing, and UL Classification for transformers.

· Underwriters Laboratories (UL) Listed:

o Transformer will include a nameplate with ‘UL’ logo.

o Further information regarding UL requirements can be found on the UL website: http://www.UL.com

o Canada - UL Listed:

§ Eaton Cooper Power Systems holds an UL file for Canada. If UL is selected in the quotation tool and the end user is located in Canada a nameplate with a ‘cUL’ logo will be provided.

· Further information regarding cUL certification can be found at the following website: https://iq.ulprospector.com/en/profile?e=184783

o The following ratings are the maximum allowed by Eaton’s UL listing within the US and Canada for transformers:

§ Class: 35kV

§ kVA: 10,000 kVA

§ Primary: 34.5kV

§ Secondary: 95kV BIL

§ Primary BIL: 200kV

§ Secondary BIL: 95kV

· Underwriters Laboratories (UL) Classification:

o Transformer will include a nameplate with UL logo

o For substation designs transformer will include additional nameplate containing fusing information only when fusing is customer-supplied. For substation designs when fusing is provided within the transformer an additional nameplate will not be provided. (Fusing will be shown on manufacturer nameplate when provided within the transformer). For all pad mount designs, regardless of the location of the fusing, fusing information will be displayed on the main transformer nameplate.

o All UL Classified transformers are required to be UL listed.

o UL Classification requires the following features:

§ Liquid level gauge for all kVA

§ Dial type thermometer and pressure vacuum gauge for 750kVA and above

§ Rapid rise relay for 2501kVA and above

§ Pressure relief device sized according to kVA rating

§ Alarm contact for pressure relief device for 2501kVA and above

§ UL Classified nameplate

o If fusing is not provided by Eaton within the transformer the customer must provide overcurrent protection to meet the respective standard (NEC 450-23). At time of purchase order, the customer must provide type of overcurrent protection, manufacturer, part number, model, rating, and I2t value. Customer provided fusing information must be reviewed and deemed adequate with respect to (put std here) by Eaton transformer engineering group prior to release to manufacturing.

· Factory Mutual (FM) Approval:

o Transformer will include additional nameplate containing fusing information provided by the factory or the end user

o The following ratings are maximum allowed by FM Approvals standard for transformers:

§ Class: 35kV

§ kVA: 10,000 kVA

o FM Indoor requires the following selectable features:

§ FR3 fluid only

§ Liquid Level gauge for all kVA

§ Dial type thermometer and pressure vacuum gauge for 750kVA and above

§ Rapid rise relay for 2501kVA and above

§ Pressure relief device sized according to kVA rating.

§ Alarm contact for pressure relief device for 501kVA and above

§ FM Indoor nameplate

o FM Outdoor requires the following selectable features:

§ FR3 fluid only

§ Liquid Level gauge for all kVA

§ Dial type thermometer and pressure vacuum gauge for 750kVA and above

§ Rapid rise relay for 2501kVA and above

§ Pressure relief device sized according to kVA rating.

§ Alarm contact for pressure relief device for 2501kVA and above

§ FM Outdoor nameplate

o If fusing is not provided by Eaton within the transformer the customer must provide overcurrent protection to meet the respective standard (FM Standard 3990). At time of purchase order, the customer must provide type of overcurrent protection, manufacturer, part number, model, rating, and I2t value. Customer provided fusing information must be reviewed and deemed adequate with respect to (put std here) by Eaton transformer engineering group prior to release to manufacturing.

The following lists contains features that would force a unit to not be UL listed, UL Classified, or FM approved:

o Out of UL Scope (both UL listing and UL Classification)

§ Motor Operator (not controlled by relay)

§ Controls with SCADA

§ N2 preservation systems

§ Tri-plex power center units

§ External Buswork

§ Jab-O style CTs

§ Non-UL Recognized/listed parts

§ Pressure transducer

§ Mineral Oil (UL Classification only)

§ No arresters (UL Hazardous only)

§ No VFIs (UL Hazardous only)

§ No Internal Control Boxes (UL Hazardous only)

o Out of FM Scope (both indoor and outdoor)

§ Mineral Oil

Bushing Inserts elbow arrester interfaces:

Interfaces used in bushing insert elbow arresters. (For more information, follow the link provided)

Loadbreak switching: Feature that allows the safe disconnection and reconnection of loads on the primary side of the system. (For more information, follow the link provided)

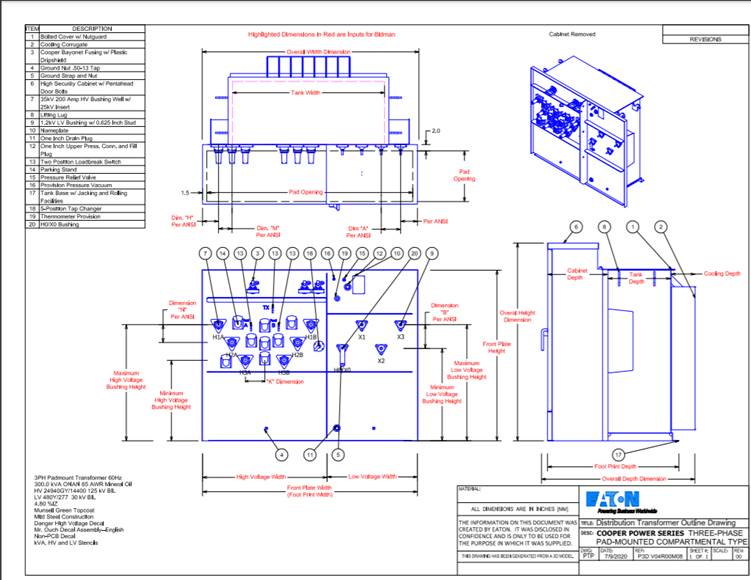

Mechanical Requirements / Limits

500 kVA and below

· Two steel pads, each with a ½-inch 13 UNC tapped hole and a minimum thread depth of 11 mm (0.44 in) shall be provided.

Above 500 kVA

· Two unpainted, copper-faced steel or stainless steel pads, 51 × 89 mm (2.0 × 3.5 in) each with two holes spaced on 44 mm (1.75 in) centers and tapped for ½-inch 13 UNC thread shall be provided. The minimum thickness of the copper facing shall be 0.5 mm (0.02 in). Minimum thread depth of the holes shall be 13 mm (0.5 in). The ground pads described shall be welded on or near the transformer base, one in the high-voltage compartment and one in the low-voltage compartment. In cases where the transformer tank and compartments are separate, these pads shall be electrically bonded

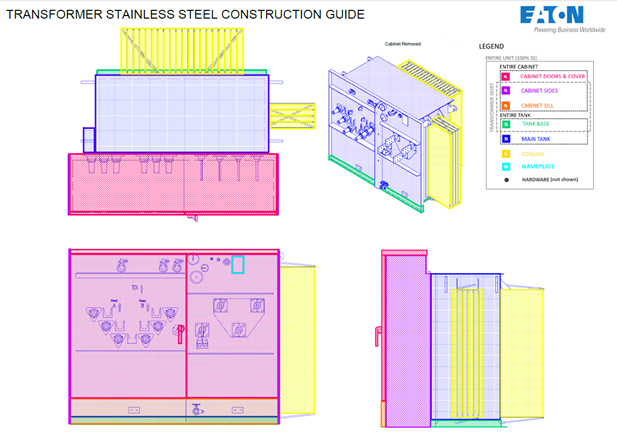

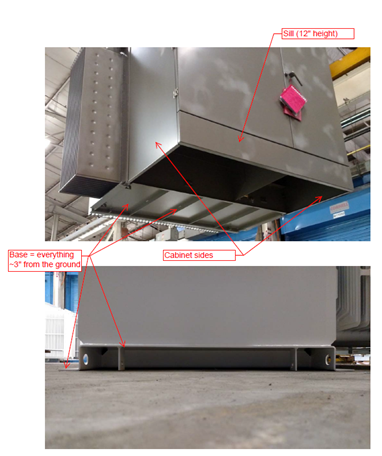

CSA cabinet:The arrangement of the transformer and cable entrance compartment shall be such that the high- and low-voltage facilities are mounted side by side on the transformer tank, with the high-voltage facility on the left when viewed from the front,The integrity of the cable entrance compartment shall be in accordance with ANSI C57.12.28, except that

a. the doors shall be approximately the same size;

b. there shall be no barrier between the HV and LV compartments;

c. the doors shall be fastened at three locations (top, middle, and bottom), and one location shall have provision for a padlock (a three-point latch shall not be required); and

d. a separate fastening of the HV door shall not be required.

A captive pentahead full-dog bolt, made of stainless steel or silicon bronze, with fixed cup(s) shall be provided as shown in Figure 9. The pentahead bolt shall be held captive to prevent removal and thread damage during operation of the door, including forceful closing. Stainless steel bolts in stainless steel threaded receptacles shall not be permitted due to the potential to gall. There shall be no exposed screws, bolts, or other fastening devices that are externally removable, except for the pentahead bolt.

The compartment side, sill, door, and roof shall be electrically bonded to the tank by flexible copper connections.

For CAD to USD conversion please use the ofllowing link:

https://www.bankofcanada.ca/rates/exchange/monthly-exchange-rates/

For all gauges, unless mentioned, Qualitrol branded gauges are the standard.

Liquid Level Gauge: Use to measure an dmonitor the fluid level within the system

Pressure Vacuum Gauge: Use to monitor pressure level within the system

Thermometer: Use to monitor temperature conditions within the system

Drain valve with sampler: Drain valve equipped with a sampler, allowing for the collection and analysis of oil from inside the tank.

Pressure relief device: Used to maintain safe pressure levels in the system.

Fault Pressure Indicators: Used to detect sudden pressure events in order to minimize potential transformer tank damage.

Metering: Used to measure various parameters within the system.

What is KYZ Pulsing? This is a meter option that sends electrical signals to upstream devices that monitor power demand or total power used. KYZ refers to Form C type contacts. K=Common Y=NO contacts Z=NC contacts. The contact states will switch based on power used, and each change is a pulse. This was previously accomplished by mechanical means when meters had a rotating dial. Currently, this is accomplished electronically through Digital I/O. An energy demand system can evaluate the pulses to calculate energy used.

Test Switches (10 pole) – Test switches allow a user to open a circuit, such as the CTs, and use meter leads to verify CT operation. Another option is to open the power supply to the meter. This could be written in specifications as “bypass switches”.

Meter Socket Forms – Form describes the meter type, not the system service voltage or configuration. The most common form used is the Form 9S. Form 9 can be used in 4-wire system or delta system. If a different system configuration is specified, contact the factory to add the system requirement to the quote bill of materials.

Voltage input – The low voltage of the transformer will power the meter through direct connection and fuse blocks connected from the low voltage bushing. If a different voltage is required in a specification, contact the factory to include the specification requirements in the quote BOM. Additional CTs will be required to meet the user specified rating.

Quoting limitations – Scope is limited to 3000A on the low voltage side of the transformer due to the JAB-0 CT max ratio selection of 3000:5.

Bayonet: Bayonet-style fuses can be removed and replaced from the outside of the transformer, allowing for quicker servicing and less down-time.